A few days ago, we received an inquiry from a customer, asking for the inner tray of the box to be customized according to the size of the outer box provided. The outer box is a suitcase mass-produced with an aluminum public mold. The inner liner is a set of product protection EVA foam lining customized according to the shape and size of the customer’s product.

The customer is currently using it for trial production, so the number required is not much, only more than ten. We preliminarily confirmed the drawings based on the size and appearance provided by the customer, and calculated the cost based on more than ten quantities. Then we quoted the price to the customer.

After getting the price, the customer replied that the suitcase they purchased was only a few dozen yuan, so how come the cost of the foam is almost twice that of the box? The cost is too high!

Here, we can understand the customer’s confusion. The customer believes that the purchase price of a suitcase as the main body is only a few dozen yuan. Logically, the inner lining as a foam lining should be very cheap.

This idea is right in that if the cost of the material is calculated alone, then the foam can indeed be made very cheap. For example, using sponge or EPE foam as the inner lining, the cost of the foam should be controlled to a few yuan. In this way, the lining should indeed be much cheaper.

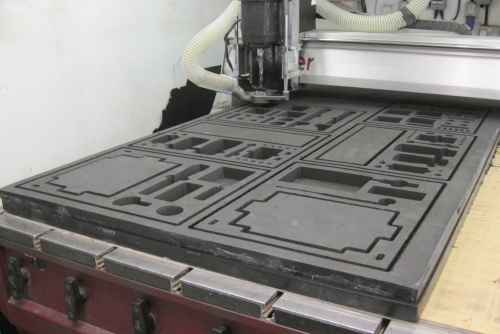

The customer overlooked another problem. The customer has requirements for the load-bearing capacity of the foam. From the material point of view, too light a material cannot protect the product, so we use high-quality EVA foam. Because the liner is customized according to the customer’s product, we need to make drawings according to the product, and then adjust the machine for production after confirmation. We can make drawings according to the customer’s product for free, but the cost of adjusting the machine is for the customer. If the quantity is too small, this cost cannot be spread out, so the unit price appears to be relatively high.

Why is the price of the outer box so cheap when the quantity is also small? Because the customer purchases the manufacturer’s batch production, and the manufacturer produces enough, so as to reduce the cost of molds, etc.

The customer can actually look at this problem from another perspective. This can be used as the cost of proofing. In the later stage of mass production, we can return the cost of the sample according to the order quantity. In this way, the price of more than ten EVA liners will become very cheap, or even free.

Leave a Reply